Whether you are a DIY enthusiast or a professional woodworker or metalworker, a drill vise is a must-have tool for you. It is essential to know how to use a drill vise correctly to ensure your safety and get the maximum out of this machine. So, how does it work, and what are the benefits?

Using this tool is not complicated, and you can easily find helpful videos and tutorials on platforms like YouTube. They offer detailed guidance on using this tool effectively. However, if you are searching for a brief summary, you are in the correct place. I will provide you with a detailed explanation of how to use drill press vise in this article. So, let’s begin the journey.

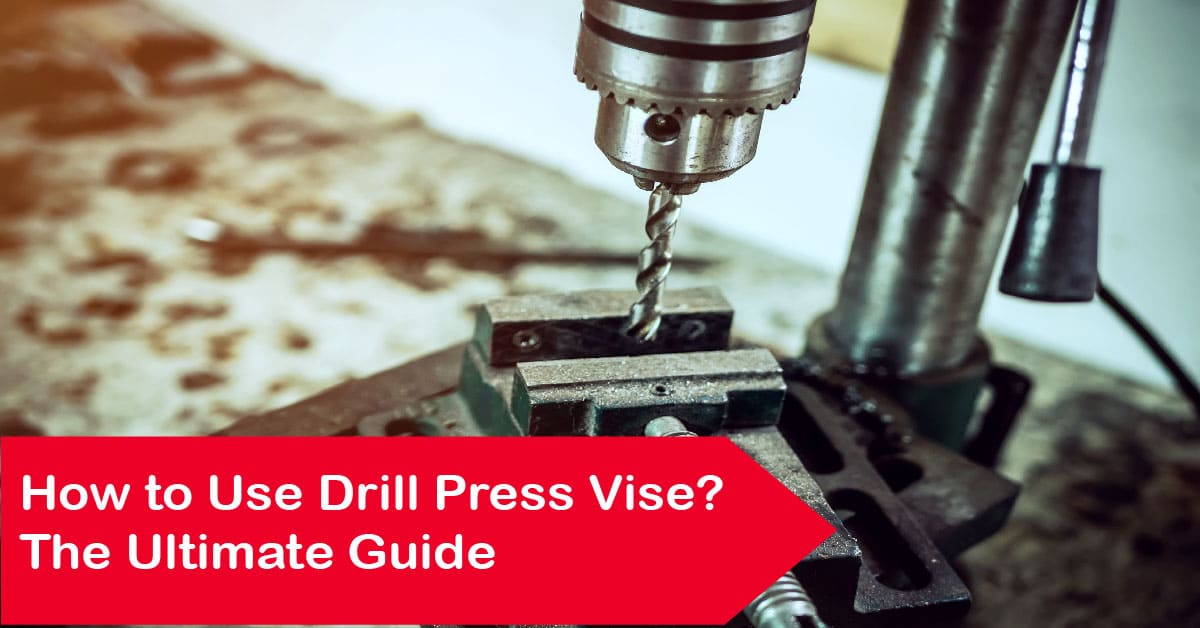

What Is a Drill Press Vise?

A drill vise is actually a handy tool that keeps your workpiece securely in place between its jaws so tightly that it will be completely unmoved when you press the drill bit into it. It’s a tool that will boost safety when you work with a drill press. Just like other vises, a drill press vise utilizes a threaded rod to bring the jaws together, creating a tight grip.

You will find different types of drill press vises out there on the market. Some clamp directly onto the table, while others utilize the miter-gauge slot for securing themselves on the table. However, these vises have their limitations. They are only able to hold small workpieces.

This is due to the fact that most of them have jaw openings that are only 6 to 7 inches wide. So, if you are working with larger workpieces, then you will need to explore other options for keeping them secure.

What Purposes Does This Tool Serve?

A drill vise is one handy tool that is often overlooked by people who have their own workshops at home. It may not be on the top of everyone’s shopping list, but let me tell you, it is incredibly useful. This tool is all about keeping your workpiece steady and secure while you drill, cut, or do any other operation. And you know what that means? It is a big safety booster!

These vises are frequently seen on drill presses. The best part is that it reduces hand fatigue from prolonged use and saves you time because you don’t require clamps or any other gripping devices to securely hold workpieces. Machinists have been using these vices for ages, but surprisingly, not many people have one in their home workshop.

Still, it is difficult to think about working on projects without this simple tool because it has lots of excellent uses. Below are a few uses of this tool:

How You Can Prepare The Drill Vise

When you are working with a drill press, it is crucial to properly prepare your vice. It might seem a bit tricky at first, but don’t worry! Whether you are using the drill press to drill some holes in wood or as a substitute for a table saw, it plays a vital role in your workshop. When you drill holes in metal, make sure to use a drill vise or clamp.

You need to secure the object or workpiece firmly between two clamps so that it does not move or slip. When cutting, remember to maintain a slow and steady motion for better control and precision. Before you start drilling, it is essential to take away the drill bit and after drilling lubricate it with some oil.

The Process of Using a Drill Vise Correctly

After setting up the drill vise as instructed, it is time to give it a go and make sure everything is working smoothly. You definitely want to test it out to ensure it is functioning correctly. Here is what you should do when using a drill press vise:

Identify the Drill Point and Mark It

Before you mount the vise on the drill press table, make sure to identify the drill point and mark it. You can simply use a marker or pencil to do this. It is really important to mark the drill point underneath the drill press table.

If you don’t, the drill point will not align with the vise’s hole, and you will end up drilling in the incorrect spot. So, take a moment to mark the drill point correctly to avoid any mishaps.

Place the Workpiece Properly

Once you have got your marking done correctly, it is time to secure the workpiece in your vise. For doing this, start by turning the handle of the vise counterclockwise to open its jaws. Make sure to open them just a bit wider than the workpiece itself. Make sure to open them just a bit wider compared to the workpiece itself. Now, carefully place the workpiece between the jaws.

It is important to avoid clamping the workpiece right at the edge because the drill press’s force and vibrations could cause it to come loose. When you place the workpiece in your drill vise, ensure the marking point is in the perfect position for the drilling process to begin smoothly.

Clamp Correctly

Now, you need to secure the workpiece or object. To do that, you will have to close the jaws by turning the same handle in a clockwise direction over the drill vise. Keep tightening the jaws of the vise with the lever until you’re confident that the object is firmly held in place. Keep in mind that you should not close the jaws very tightly.

Doing so can cause damage, especially to softer woods like poplar or pine. Once again, it is crucial to ensure the workpiece is securely held so that it doesn’t slip while you are drilling. You can test this by attempting to pry your workpiece free from the vise’s jaws. If it doesn’t work, then you can proceed with your work safely.

Properly Align The Drill with The Drill Point

Now, let’s ensure you have the drill vise in the right position underneath the drill and securely fastened to the drill press table. This will ensure that you will be able to drill precisely in the correct place where you marked in the first stage. To align your drill with the marked point on the workpiece, it is crucial to know the drill press swing of your specific drill press.

Otherwise, the column might prevent you from drilling in that particular location. Once you have that information, you can proceed to secure your drill vise properly. Now, here comes the question: how can a vice be attached to a drill press?

It can be done in two ways. If your vise has slots, you can secure it using a bolt and nut through those slots or through the hole of the drill press’s base and in the middle of the drill press table. In case your vise doesn’t have slots, you can use clamps to secure it.

Begin Drilling The Hole

It is time to begin drilling. One very important thing you don’t want to forget is to set the speed of the drill presses correctly. Also, before you start drilling, give the alignments one final check to make sure everything is in the right place. When you are drilling holes that don’t completely penetrate the wood, it’s a good idea to set the drill depth just right.

For this reason, you can utilize the depth gauge to regulate how deep the drilling will be. This maintains track of how far into the workpiece you like the spindle to keep drilling. Now, start the drilling machine and slowly lower the drill press. Just before the drill makes contact with the wood it’s advisable to descend the drill slowly until contact is achieved between the workpiece and the drill.

When the drill starts cutting into the wood, you can apply light pressure and push the material. It will ensure that the drilling process goes smoothly and cleanly. You have now mastered the proper use of a drill press vice after completing this final phase.

Safety Precautions that You Should Take When You Use a Drill Vise

Using a drill press vise can be pretty risky if you are not careful. So, before you get started, make sure that the vise is firmly attached to a drill press table. Loose vise can cause big trouble and potential injuries, so double-check it. Also, don’t forget to wear eye protection to shield yourself from any flying debris that might come your way and injure your eyes.

Now, let’s talk about securing and aligning your workpiece properly. You need to attach the workpiece to the vise using C-clamps, clamps, or, of course, another drill vise. The vise should have a good grip on your workpiece from any position on the drill press table. If needed, adjust the vise’s jaws to fit the diameter of your workpiece.

How Can You Choose the Best Vise?

So, now that you have gotten the hang of using a drill press vise, you are probably wondering which one is the best, right? Well, let me tell you, there are a ton of options out there to choose from. It can be overwhelming! You will come across different sorts of drill vises, each designed for specific purposes. But fear not, because I have got some tips to help you make a smart choice.

When it comes to finding the best vise, it is all about looking out for a few key factors. Don’t worry, I will keep it simple for you. By considering these simple factors, you will be able to make a good selection without any hassle.

First and foremost, it is crucial to determine the specific purpose you have in mind for the drill press vise. This tool’s purpose is to hold the metal or wood while you are drilling. Whether you will be working with plastic, metal, wood, or any other materials, understanding your intended use will help you decide the ideal size of the vise and any additional features you might require.

Secondly, once you have a clear purpose in mind, it is advisable to opt for a reputable brand that is known for delivering good quality products. This way, you can have confidence in the vise’s durability and performance. The third important aspect to consider is the profile of the vise.

A lower profile allows for a larger workpiece to be securely clamped in the vise, providing greater versatility and flexibility. Fourthly, it is beneficial to search for models that offer easy clamping mechanisms, often featuring useful slots that simplify the process. This feature can save you time and effort while ensuring a secure grip on the workpiece.

Lastly, you will need to establish your budget for purchasing a drill vise. By determining how much you are willing to spend, you can narrow down your options and focus on finding the best vise within your price range.

Conclusion

When it comes to using a drill press vise, it is crucial to do your research before making a purchase. There are loads of different kinds of drill vises out there, each with its own advantages and disadvantages. Once you have gathered all the necessary information, you will be in a much better position to choose the perfect vise for your needs.

Also, don’t forget about safety! It is very important, especially when dealing with heavy-duty drilling machines. So, make sure you invest in some safety equipment to keep yourself protected and avoid any unfortunate injuries. Finally, that is all you require to learn about how to use drill press vise, and hopefully, you have liked this article.