Porcelain tiles are known for their durability, hardness, and resistance to water, stains, and scratches, making them an ideal choice for floors, walls, and countertops in kitchens, bathrooms, and other high-traffic areas.

However, cutting porcelain tiles can be challenging, requiring specialized tools and techniques to prevent damage, cracking, or chipping. One of the most popular tools for cutting porcelain tiles is the angle grinder, a versatile power tool that uses various types of blades to cut through hard materials, such as metal, concrete, and stone.

Porcelain tile is a popular choice for floors, walls, and other surfaces in homes and commercial settings due to its durability, resistance to moisture and stains, and aesthetic appeal. However, cutting porcelain tile can be a challenging task that requires specialized tools and techniques to achieve a precise and clean cut without damaging the tile or risking injury.

One of the most effective tools for cutting porcelain tile is an angle grinder, which uses a rotating abrasive disc to slice through the tile. However, the quality and effectiveness of an angle grinder blade can vary greatly depending on its design, materials, and compatibility.

In this article, we will explore some of the key factors to consider when selecting the best angle grinder blade for cutting porcelain tile, as well as some of the top-rated and most recommended options on the market. Whether you are a DIYer or a professional contractor, this guide will help you find the right blade and achieve a smooth and accurate cut every time.

Best Angle Grinder Blades for Cutting Porcelain Tile:

Now that we will cover the essential factors to consider when choosing an angle grinder blade for cutting porcelain tile later. For now, let’s review some of the top-rated and most recommended blades on the market. These blades have been selected based on their quality, performance, durability, user feedback, and compatibility with various angle grinders.

1. Bosch DBX541P 5 In.

This diamond blade is designed for fast and smooth cutting of a variety of materials including concrete, brick, and stone. It features a segmented rim for optimized cooling and reduced debris, and the X-LOCK system makes it easy to change blades without the need for tools.

Pros

- Premium diamond blade for smooth and fast cuts

- Segmented design for effective debris removal

- Extended lifespan due to high-quality materials

Cons

- More expensive than some other diamond blades on the market

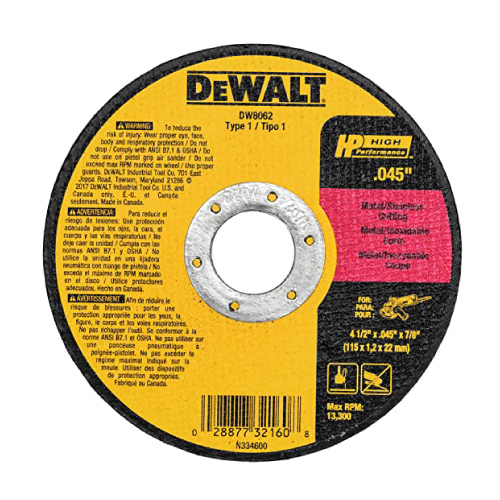

2. DEWALT Cutting Wheel, 4-1/2-Inch(DW8062B5)

This pack of five cutting wheels is designed for use with a variety of metals including steel and aluminum. The high-performance aluminum oxide grain delivers long life and fast cutting speed.

Pros

- Affordable pack of 5 cutting wheels

- Durable and long-lasting

- Can be used on a variety of materials

Cons

- Not specifically designed for cutting harder materials like tile or porcelain

3. BSRTTOOl 5 Inch Diamond Saw Blade Dry or Wet

This diamond saw blade is suitable for cutting a variety of materials including porcelain, stone, marble, granite, concrete, and ceramics. It is compatible with both wet and dry cutting methods.

Pros

- Can be used both wet and dry

- Suitable for cutting a variety of materials including tile, stone, and concrete

- Comes with a protective case

Cons

- Some users have reported that the blade can be prone to chipping or breaking

4. DEWALT Diamond Blade, 4-1/2-Inch (DW4765)

This diamond blade is designed for cutting porcelain tiles and features an extended performance diamond matrix for long life and enhanced material cutting. It can be used with both wet and dry cutting methods.

Pros

- Specifically designed for cutting porcelain tile

- Can be used wet or dry

- Durable and long-lasting

Cons

- More expensive than some other diamond blades on the market

5. EZARC 4-1/2-inch Diamond Blade

These diamonds saw blades are designed for cutting porcelain, ceramic, granite, and marble tiles. They feature a super-thin design for fast and precise cutting, and the reinforced flange provides added strength and stability.

Pros

- Super thin design for precise and clean cuts

- Suitable for cutting a variety of materials including tile, granite, and marble

- Comes with a protective case

Cons

- Some users have reported that the blade can be prone to chipping or breaking

6. Bosch DB343C 3″ Premium Continuous Rim Diamond Blade

This diamond blade is designed for clean cutting of materials such as tiles, ceramics, and glass. The continuous rim design provides smooth and accurate cuts, and the blade is compatible with a range of tools.

Pros

- Premium diamond blade for smooth and fast cuts

- Segmented design for effective debris removal

- Long lifespan due to high-quality materials

Cons

- More expensive than some other diamond blades on the market

7. ROK 4-1/2-inch Diamond Saw Blade Set

This pack of three diamond saw blades is designed for use with a variety of materials including concrete, brick, and stone. They feature a turbo rim design for fast and smooth cutting, and the reinforced core provides added strength and durability.

Pros

- Affordable pack of 3 diamond blades

- Suitable for cutting a variety of materials including tile, stone, and concrete

- Durable and long-lasting

Cons

- Some users have reported that the blades can be prone to chipping or breaking

8. Makita E-02668 4-1/2″ Diamond Blade

This diamond blade is designed for use with a range of materials including concrete, brick, and tile. It features a continuous rim design for smooth and precise cuts, and the high-quality diamond matrix provides long life and enhanced performance.

Pros

- Continuous rim design for smooth and fast cuts

- Suitable for cutting a variety of materials including tile, stone, and concrete

- Durable and long-lasting

Cons

- More expensive than some other diamond blades on the market

9. QEP 6-4001Q Diamond Blade

This diamond blade is designed for use with wet tile saws and is suitable for cutting a range of materials, including ceramic tiles. The continuous rim design provides smooth and accurate cuts, and the blade is compatible with a range of tools.

Pros

- Specifically designed for wet tile saws

- Suitable for cutting ceramic tile

- Affordable

Cons

- Not suitable for cutting harder materials like porcelain or stone

Factors to Consider When Choosing an Angle Grinder Blade for Cutting Porcelain Tile

Before we dive into the specific brands and models of angle grinder blades for cutting porcelain tile, it’s essential to understand the critical factors that determine their quality and suitability for this task. These factors include the type of blade, the size of the blade, the quality of the blade, and compatibility with the angle grinder.

Type of Blade

There are three main types of angle grinder blades that are commonly used for cutting porcelain tile: continuous rim diamond blades, segmented rim diamond blades, and turbo rim diamond blades. Each type has its unique features and benefits, depending on the type of tile, the thickness of the tile, and the desired cutting speed and accuracy.

Continuous Rim Diamond Blades

These blades have a smooth, continuous edge that provides a precise and clean cut without chipping or cracking the tile. They are ideal for cutting thin, delicate, or intricate porcelain tiles, as they reduce the risk of damaging the tile or leaving rough edges. However, continuous rim diamond blades are slower than other types and tend to wear out faster due to their fine grit and narrow kerf.

Segmented Rim Diamond Blades

These blades have a segmented edge consisting of several teeth or segments that cut through the tile rougher and faster. They are ideal for cutting thick, dense, or hard porcelain tiles, as they generate more power and speed than continuous rim diamond blades. However, segmented rim diamond blades may leave rough edges or create more dust and noise than other types, which can be a safety and health concern.

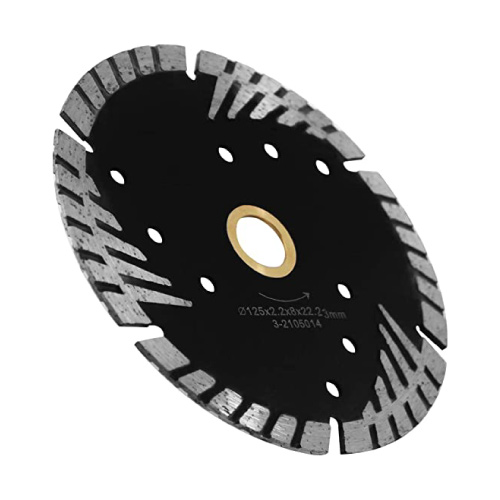

Turbo Rim Diamond Blades

These blades have a hybrid design that combines the features of continuous rim and segmented rim diamond blades. They have a serrated edge that alternates between smooth and segmented teeth, providing a balance between precision and speed. They are ideal for cutting medium-thick or moderately dense porcelain tiles, as they can cut through them quickly and smoothly without compromising the quality or safety of the cut. However, turbo rim diamond blades may be more expensive than other types and require a higher level of maintenance and cleaning.

Size of Blade:

Another important factor to consider when choosing an angle grinder blade for cutting porcelain tile is the size of the blade, which typically ranges from 4 to 7 inches in diameter. The size of the blade can affect the cutting depth, the cutting speed, and the stability of the angle grinder.

In general, a larger blade can cut deeper and faster than a smaller blade, but it may require a more powerful and stable angle grinder to handle the weight and torque of the blade. Conversely, a smaller blade may be more maneuverable and lightweight, but it may need help to cut through thick or dense porcelain tiles.

Quality of Blade

The quality of the blade refers to its material composition, hardness, and sharpness, which can affect the blade’s durability, performance, and safety. A high-quality angle grinder blade for cutting porcelain tile should be made of industrial-grade diamond particles bonded to a sturdy steel core.

The diamond particles should be evenly distributed and firmly attached to the core, to ensure consistent and efficient cutting. The steel core should be heat-treated and tempered to resist deformation, warping, or cracking under high pressure and temperature. The blade should also be sharp enough to slice through the tile without applying excessive force or vibration, which can damage the tile or the blade.

Compatibility with Angle Grinder

The last factor to consider when choosing an angle grinder blade for cutting porcelain tile is the compatibility with the angle grinder itself. Not all angle grinders are suitable for cutting porcelain tile, as they require specific features and specifications to handle the high demands of this task. Some of the key features to look for in an angle grinder for cutting porcelain tile include:

High amperage and wattage: This indicates the power and speed of the angle grinder, which can affect the cutting depth and speed of the blade. A higher amperage and wattage can provide more torque and RPM, which can help the blade cut through the tile faster and smoother.

Variable speed control

This allows the user to adjust the speed of the angle grinder according to the type and thickness of the tile, as well as the desired level of precision and control. A variable speed control can also prevent overheating or burning the tile, which can occur if the blade spins too fast or too slow.

Adjustable guard

This protects the user from flying debris and dust, which can be generated during cutting. The guard should be adjustable to accommodate different blade sizes and cutting angles, while still providing sufficient coverage and visibility.

Anti-vibration technology

This reduces the vibration and kickback that the angle grinder generates during operation, which can reduce the strain and fatigue on the user’s hands and arms. Anti-vibration technology can also prevent the blade from skipping or jumping on the tile, resulting in uneven or jagged cuts.

Conclusion

Choosing the best angle grinder blade for cutting porcelain tile requires careful consideration of various factors such as blade size, rim type, diamond quality, core material, and angle grinder compatibility.

Users can achieve a precise, smooth, and efficient cut without damaging the tile or the blade by selecting a blade that meets these criteria. Regardless of which blade is chosen, it is essential to follow proper safety guidelines and techniques when using an angle grinder for cutting porcelain tile, such as wearing protective gear, securing the tile, and avoiding excessive force or pressure. Cutting porcelain tile with the right tools and techniques can be a manageable and rewarding task for DIYers and professionals.